Since 1963, Delta Steel, Inc. has been a leader in the global structural steel market. Because of our capable machines, skilled experts, and utmost dedication to our customers, we are now one of the largest carbon steel plate suppliers in the southwest United States. Our specialization includes producing high-quality carbon steel plates in various sizes, widths, and lengths, depending on customer specifications.

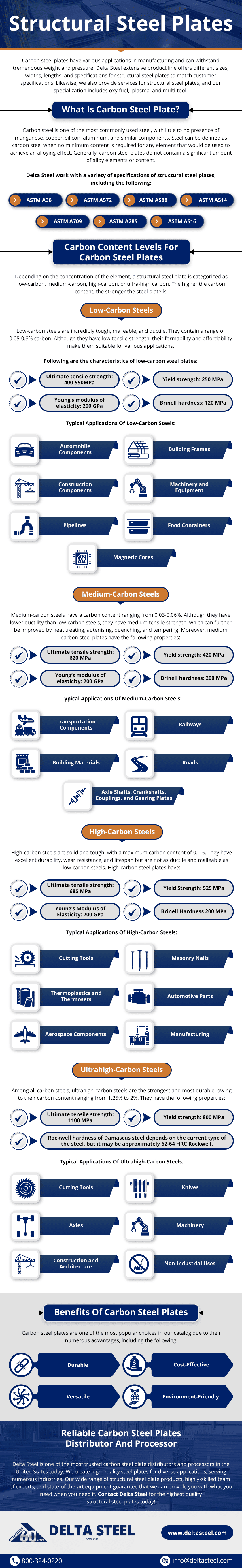

What Is Carbon Steel Plate?

Carbon steel is one of the most commonly used steel, with little to no presence of manganese, copper, silicon, aluminum, and similar components. Steel can be defined as carbon steel when no minimum content is required for any element that would be used to achieve an alloying effect. Generally, carbon steel plates do not contain a significant amount of alloy elements or content.

Delta Steel work with a variety of specifications of structural steel plates, including the following:

ASTM A36

Standard specification for carbon structural steel that covers shapes of structural quality for use in riveted, bolted, welded construction of bridges, buildings, and general structural purposes. Learn More+

ASTM A572

Standard specification for high-strength low-alloy structural steel with five grades of shapes intended for riveted, bolted, or welded construction of bridges or for other construction applications. Learn More+

ASTM A588

Standard specification for high-strength low-alloy structural steel, exact as ASTM A572 but is intended primarily for use in welded bridges and buildings where savings in weight or added durability is essential. The atmospheric corrosion resistance of this steel in most environments is substantially better than that of carbon steel with or without copper addition. Learn More+

ASTM A514

Standard specification for high-yield-strength quenched and tempered alloy steel plate, suitable for welding. Learn More+

ASTM A709

Standard specification for carbon and high-strength low-alloy and quenched-and-tempered alloy structural steel plates for bridges that cover carbon HSLA plates. Seven grades are available in four yield strength levels. Learn More+

ASTM A285

Standard specification for pressure vessel plates, carbon steel, and low-and-intermediate-tensile strength. Learn More+

ASTM A516

Standard specification for pressure vessel plates, carbon steel, for moderate-and-lower-temperature service. Learn More+

Carbon Content Levels For Carbon Steel Plates

Depending on the concentration of the element, a structural steel plate is categorized as low-carbon, medium-carbon, high-carbon, or ultra-high carbon. The higher the carbon content, the stronger the steel plate is.

Low-Carbon Steels

Low-carbon steels are incredibly tough, malleable, and ductile. They contain a range of 0.05-0.3% carbon. Although they have low tensile strength, their formability and affordability make them suitable for various applications. Following are the characteristics of low-carbon steel plates:

- Ultimate tensile strength: 400-550MPa

- Yield strength: 250 MPa

- Young’s modulus of elasticity: 200 GPa

- Brinell hardness: 120 MPa

Typical Applications Of Low-Carbon Steels:

- Automobile components

- Building frames

- Construction components

- Machinery and equipment

- Pipelines

- Food containers

- Magnetic cores

Medium-Carbon Steels

Medium-carbon steels have a carbon content ranging from 0.03-0.06%. Although they have lower ductility than low-carbon steels, they have medium tensile strength, which can further be improved by heat treating, autenising, quenching, and tempering. Moreover, medium carbon steel plates have the following properties:

- Ultimate tensile strength: 620 MPa

- Yield strength: 420 MPa

- Young’s modulus of elasticity: 200 GPa

- Brinell hardness: 200 MPa

Typical Applications Of Medium-Carbon Steels:

- Transportation components

- Railways

- Building materials

- Roads

- Axle shafts, crankshafts, couplings, and gearing plates

High-Carbon Steels

High-carbon steels are solid and tough, with a maximum carbon content of 0.1%. They have excellent durability, wear resistance, and lifespan but are not as ductile and malleable as low-carbon steels. High-carbon steel plates have:

- Ultimate tensile strength: 685 MPa

- Yield Strength: 525 MPa

- Young’s Modulus of Elasticity: 200 GPa

- Brinell Hardness 200 MPa

Typical Applications Of High-Carbon Steels:

- Cutting tools

- Masonry nails

- Thermoplastics and thermosets

- Automotive parts

- Aerospace components

- Manufacturing

Ultrahigh-Carbon Steels

Among all carbon steels, ultrahigh-carbon steels are the strongest and most durable, owing to their carbon content ranging from 1.25% to 2%. They have the following properties:

- Ultimate tensile strength: 1100 MPa

- Yield strength: 800 MPa

- Rockwell hardness of Damascus steel depends on the current type of the steel, but it

- may be approximately 62-64 HRC Rockwell.

Typical Applications Of Ultrahigh-Carbon Steels:

- Cutting tools

- Knives

- Axles

- Machinery

- Construction and architecture

- Non-industrial uses

Benefits Of Carbon Steel Plates

Carbon steel plates are one of the most popular choices in our catalog due to their numerous advantages, including the following:

- Durable. Strong, sturdy, and shock-resistant carbon steel plates are highly recommended for structural, construction, and industrial applications. Their high tensile strength and hardness are their most famous qualities.

- Cost-effective. Carbon steel plates share similar characteristics with aluminum and stainless steel but are far more inexpensive than the two.

- Versatile. The variety of carbon content levels makes the carbon steel plate a highly versatile material. It is also available in various dimensions, unlike other materials.

- Environment-friendly. Carbon steels have a long life, reducing the need for frequent replacement. Additionally, they are also one of the most commonly recycled materials.

Reliable Carbon Steel Plates Distributor And Processor

Delta Steel is one of the most trusted carbon steel plate distributors and processors in the United States today. We create high-quality steel plates for diverse applications, serving numerous industries. Our wide range of structural steel plate products, highly-skilled team of experts, and state-of-the-art equipment guarantee that we can provide you with what you need when you need it. Contact Delta Steel for the highest quality structural steel plates today!