Structural Steel Services

Delta Steel is one of the largest structural steel service centers in the United States, offering an extensive range of top-quality products and value-added services.

Since 1963, we have met the needs of the structural steel market, serving a diverse range of industries in 17 states and countries. We customize our strategically located facilities to meet the unique demands of the regions they serve, ensuring efficient, economical, and just-in-time (JIT) delivery of our quality materials.

We maintain state-of-the-art processing equipment, and our structural steel processing services include cambering, drilling, plate burning, press brake forming, robotic processing, saw cutting, and T-splitting.

At Delta Steel, we continually strive to develop mutually profitable and long-lasting relationships with our customers, employees, and business partners, and we never stop searching for the best solutions to enhance our products and structural steel processing capabilities.

Plate Burning

Delta Steel provides plate burning services that utilize both Computer Numerical Control (CNC) Oxy-Fuel and Hi-Definition Plasma cutting methods to achieve precision cuts on steel plates and sheets.

- Hi-Definition Plasma Cutting

Hi-Definition Plasma cutting works by sending an electrical arc through compressed air or an inert gas. The arc converts the gas into a plasma that can melt the metal workpiece. Once the melting is complete, the remains are blown away, leaving the desired shape.

The advanced technique is controlled by CNC instructions, allowing for complex and intricate designs based on customer-supplied hard copy blueprints or drawings (in .dwg or .dxf formats).

- Oxy-Fuel Cutting

The Oxy-Fuel cutting process provides a cost-effective solution for heavy-duty applications, utilizing a combination of fuel gases and oxygen to cut through thick steel plates. Delta Steel employs cutting-edge machinery to accommodate the specific requirements of a diverse range of projects, with the capabilities to consistently cut plates up to 8″ thick and 100′ long.

Drilling

Delta Steel offers unparalleled drilling services that can handle the demands of various structural steel components. Utilizing large bed CNC drills allows us to form holes with tapping up to 1″ and diameters of up to 3.5″.

Our advanced equipment includes beam cambering machines, punch presses, and large bed CNC drills, which allows us to:

- Create Counterbores and Countersinks

- Cut to Length

- Drill

- Mill Features

- Tap Holes

Using coolant from the drilling table reservoir ensures chips get blown away as soon as they emerge from the hole, maintaining the integrity of the material and creating a smooth finish. This process extends the lifespan of the drilling equipment and enhances the quality of the end.

Robotic Processing

At Delta Steel, our robotic processing services effectively automate the process of cutting complex angles and shapes into high-quality structural steel components. Converting engineering data to CNC robotic coping machines presents the following advantages:

- Enhances Quality

- Improves Safety

- Lowers Costs

- Minimizes Material Preparation

- Reduces Coping Time

Robotic processing enables high-quality, precise cuts, holes, and incisions without inconsistencies, mistakes, or improper finishes. CNC coping also eliminates the risk of human error, ensuring accurate and consistent results for every project.

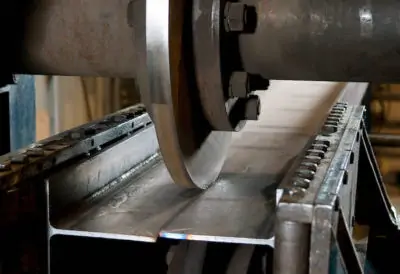

Saw Cutting

Delta Steel offers cutting capabilities that produce clean, accurate cuts for a wide variety of steel profiles, including solid rounds, pipes, tubes, and beams. Our in-house operating system utilizes transfer tables and roller conveyors that feed material in and out of the saws. We also rely on automated nesting software to reduce scrap, maximize material yield, and support high-volume, precision production.

Our saw cutting services meet the demands of various applications in the following industries, delivering reliable, efficient solutions for structural steel processing:

- Aerospace

- Automotive

- Construction

- Consumer Product Manufacturing

- General Machining

- Maintenance & Repair

- Military & Defense

- Steel Service Centers

At Delta Steel, our skilled technicians are experienced in saw cutting, removing raised edges or burrs, and similar services and requirements. We also utilize advanced equipment to ensure each cut is performed with the highest level of accuracy, contributing to the overall performance and quality of the final product.

Forming (Press Brake)

Delta Steel’s press brake forming services include the use of state-of-the-art machinery that ranges from 650 to 2,200 tons and up to 60′ in length. The press brake can create complex bends in steel sheets and plates (including Z, W, V, and U shapes) for industrial and structural applications by clamping the plate or sheet between the stationary die and movable punch.

Our press brake forming services offer versatility and adaptability for a diverse range of sheet metal applications, providing an ideal solution for large-scale projects requiring high precision, efficiency, and repeatability. Delta Steel can deliver high-quality components that meet the highest quality standards and exact specifications.

Cambering

At Delta Steel, we utilize cambering techniques to enhance the structural integrity of beams, making them a preferred material choice for bridges, buildings, and other construction applications.

Our cambering process can accommodate lengths starting at 20′, supporting beam sizes up to WF 40 x 397# while offering the following benefits:

- Improves Load Distribution

- Introduces Structural Beams to Controlled Upward Curves

- Minimizes Deflection

Cambered beams from Delta Steel help our clients achieve optimal longevity and performance in their structures.

T-Splitting

Delta Steel offers T-Splitting services that efficiently divide wide flange channels or beams into two precise T-sections. This technique of splitting is often used in support systems and roof trusses, providing flexible solutions for various construction applications. Using both thermal and rotary splitting methods, our equipment can accommodate beam sizes up to W30 x 108 with a 5/8″ or less web thickness.

Structural Steel Services from Delta Steel

With over six decades of proven industry experience as a leading structural steel service center, Delta Steel delivers reliable and innovative processing solutions by embracing advanced technology, cutting-edge equipment, and a customer-centric approach.

Our combination of speed, precision, and quality makes us the preferred choice for structural steel services across OEM manufacturing, construction, infrastructure, and energy sectors.

We offer low-cost, high-quality services with quick turnaround, on-time delivery, and competitive rates. Our unwavering commitment to continuous improvement and customer satisfaction ensures we meet or exceed client expectations in every project.

Contact us today to learn more about our process capability and structural steel processing services.